The Venerable Rocker Bogie Robot

Background

I have always admired the Mars Rovers and their drive train design. Called a "Rocker Bogie", it has the singular distinction of operating on another planet over varied terrain that is simultaneously rocky and sandy. It is thoroughly documented on a NASA website, along with CAD files and source code, which can be leveraged as a starting point for design variants.

Being a bit lazy (and time-constrained), for the last few years I have been on the prowl for a kit that would include all of the parts I would need to build my own Rocker Bogie-equipped chassis for use in terrestrial applications. Alas, such a kit has proven to be more elusive than I expected.

Most of the kits are targeted at the toy market, seeking to sell a Mars Rover replica, and do not implement all of the mechanical features of the Rocker Bogie design that enable it to scale obstacles exceeding the diameter of the drive wheels. The few that are targeted to the research community provide the Rocker and the Bogie mechanism, but frequently leave off the "Differential", a critical component that allows the weight over each wheel to be more evenly distributed. This allows the robot chassis to avoid getting stuck in sandy soil that would otherwise cause the wheel to dig itself into a hole.

Thankfully, I have good news! I have found not one, but two full-featured Rocker Bogie kits, one for less than $150 (USD) and another more expensive option with detailed instructions and source files to allow you to build a highly accurate reproduction of the Mars Rover with more payload capacity than the less expensive kit.

Let's look at both kits in the next few sections, and then later I will extoll the virtues of the Rocker Bogie drive train.

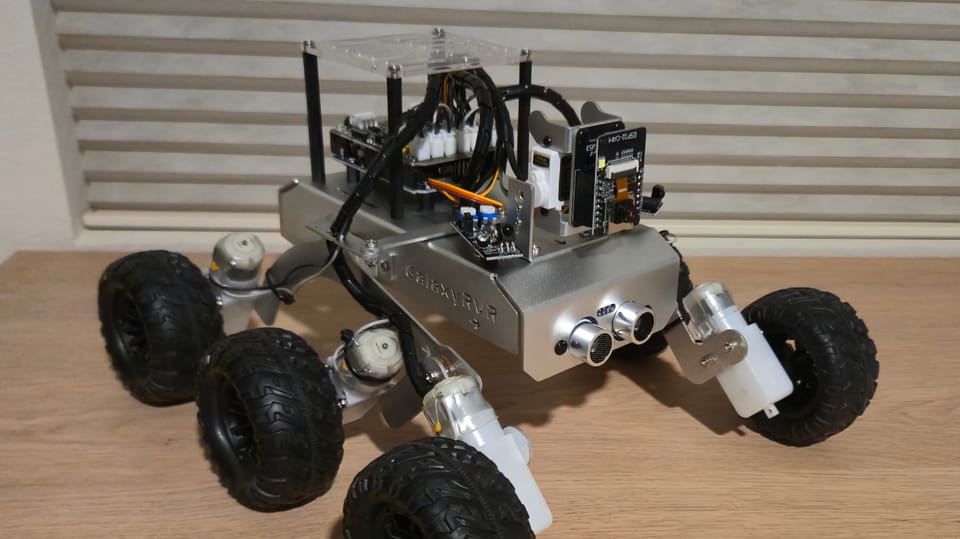

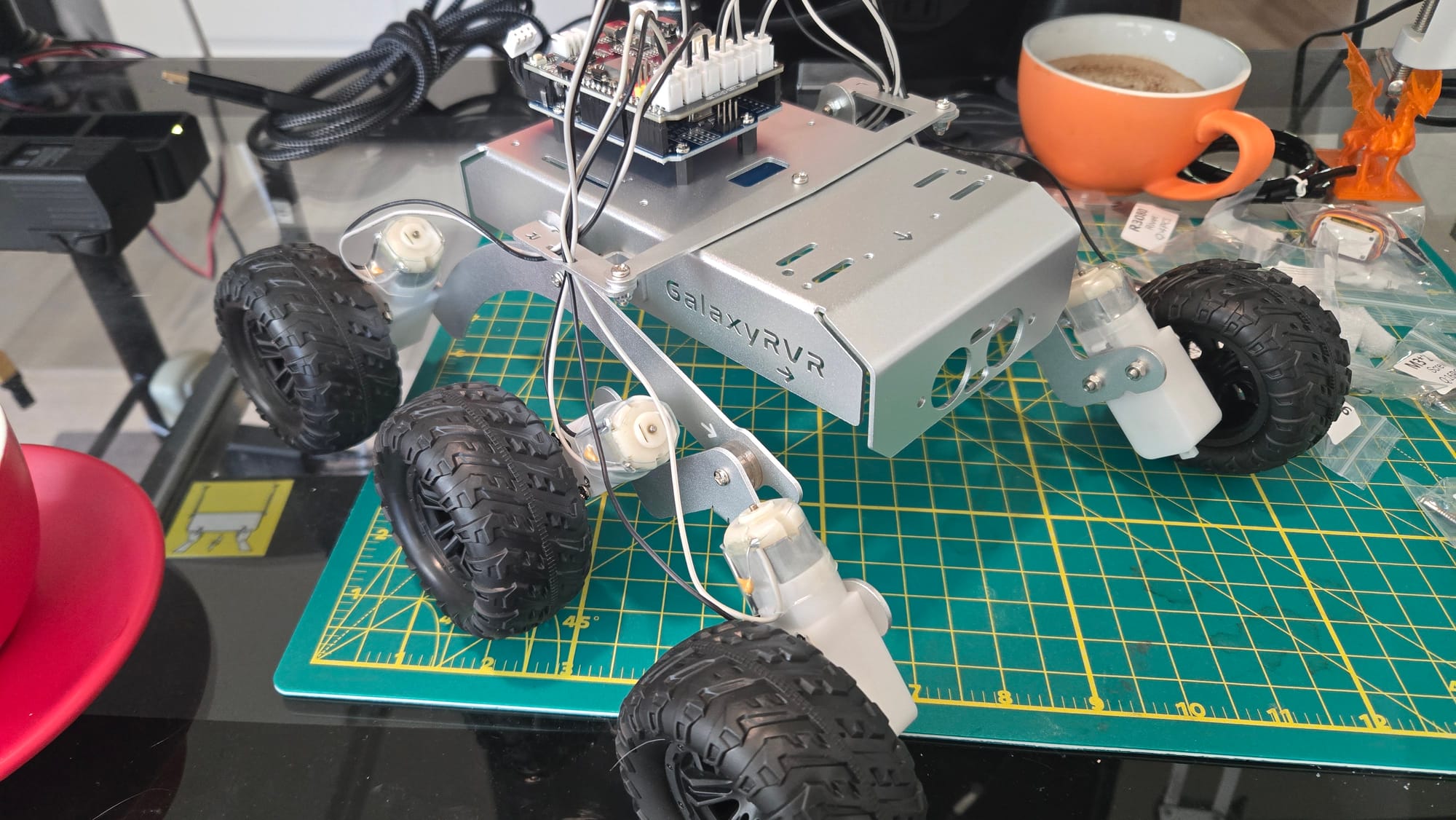

GalaxyRVR

The low-cost kit, officially named the "GalaxyRVR", includes an Arduino Uno R3 and an ESP32-CAM module. The latter provides connectivity to a smartphone that can be used for remote control, in addition to a video stream from the onboard OV2640 camera. Two IR sensors are used for obstacle avoidance, positioned at the left and right corners of the robot to detect obstacles just outside the field-of-view of the camera. An ultrasonic sensor is positioned between the IR sensors and points forward to detect obstacles in the path of motion. The image at the top of this page shows both the IR and ultrasonic sensors at the front of the robot.

The Rocker Bogie drive train consists of six independent DC motors with a gear box that connects directly to the hub of the wheel. Steering is provided by differential control of the left and right side motors, unlike the original Mars Rover which can independently pivot the two front and two rear motors to achieve a zero turning radius. Normally I would say that the lack of steering motors on the GalaxyRVR is a handicap, but considering its small size and six independent motors it has more than enough power to turn in place, even if the wheels do drag a bit.

The key benefit of this robot is the mechanically accurate reproduction of the "Differential" which appears as a strait bar mounted to the top of the robot just in front of the Arduino Uno board (see the image below). More discussion on the physics of the Rocker Bogie design is provided later in this article.

The multitude of screws, wires, and parts are nicely packaged in individual bags clearly labeled and later referenced in the assembly instructions. Much to my surprise the assembly instructions are actually printed and well written. The fact that it is printed is handy when your work bench faces away from the computer screen as mine does, and the accurate illustrations of each assembly step shows an extra bit of attention to detail that I appreciate.

Thus far my only criticism of the robot is the lack of alignment between the wheels. None of the wheels point straight ahead and are toed-in/out at differing angles. This seems to be caused by a slight bend in the Bogie arm and by variability in the plastic hubs of each wheel. Essentially this is a level of manufacturing tolerance which is not possible with the low cost materials used. In any case, I had no problem getting the robot to move forward in a straight line.

The GalaxyRVR is available for purchase on the manufacturer's website and also on Amazon. It is currently priced at around $130, but is just $104 dollars during Amazon Prime Day. If you were to attempt to buy the parts separately you would be hard pressed to match this price.

Upgraded Wheels

I have found replacement wheels with a more rigid hub, possibly improving the overall wheel alignment, as describe above.

Replacement wheels, possibly providing more rigidity.

Video Demo

This video shows the Rocket Bogie in action, scaling a mountain of pillows much higher than the wheel diameter.

DIY Mars Perseverance Rover Replica

A few years ago, I was lucky enough to find a Rocker Bogie project that provides everything I could hope for: lots of payload capacity, 3D printed parts, great documentation, open source, and open hardware. It is supported by the creator on his website "How to Mechatronics". Both Solidworks and STL files are provided on Cults3D.

The parts list requires a good bit of effort to acquire, and I spent many weeks waiting for everything to arrive. I have not yet started the 3D printing process or the minor fabrication required for a few of the metal parts. This means I can't really provide an endorsement of the working model, but I am eager to get started.

The Magic of the Rocker Bogie

The most comprehensive information on the history and design of the Rocker Bogie is available here. The key feature of this drive train is its ability to climb obstacles larger than the wheel diameter, while keeping the chassis relatively level. It does this without the benefit of springs or shocks and without getting bogged down in loose ground.

Being a mere software engineer, I find the design that accomplishes this to be magical! There are two arms, the larger is the Rocker and the smaller is the Bogie. The front of the Rocker arm has a single wheel attached, and the rear has the smaller Bogie arm attached. The Bogie arm has two more wheels attached to either side of itself, for a total of three wheels. This design allows the rear wheels to move independently of the front wheel as it rides over obstacles that are no longer in contact with the front wheel.

The Differential is the other element of this design that connects the Rocker arms on either side of the robot. When the wheels on the Rocker arm make contact with uneven terrain, it will rotate. This rotation causes deflection of the attached differential arm, forcing the Rocker arm on the opposite side to move in the opposite direction. So when the front wheel of the Rocker arm on the left is trying to climb a large rock and is raised upward, the Rocker arm on the right will be forced to rotate in the opposite direction, causing its attached wheel to move downward. As the wheels on one side are raised, the wheels on the other side are lowered. If both sides encounter a rock of equal height, the downward force on each wheel will be equally distributed, despite the unequal distribution of the weight of the payload carried by the robot chassis. The animations from the website referenced below depict the connection between the Differential and Rocker Bogie arms.

Conclusion

Modern civilization has granted us many smooth surfaces to traverse with our robots. If we are ever to realize the promise of autonomous off-road robots, however, we will need this type of drive train. Albeit not as robust as legged robots, the Rocker Bogie and Differential, demonstrate that the wheel has not outlived its usefulness.

Comments ()